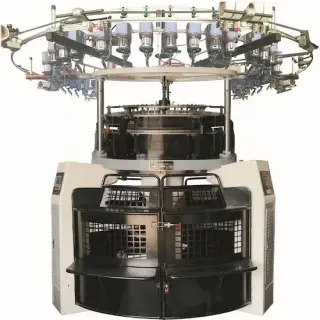

The double jersey knitting machine, also referred to as the circular knitting machine, is a mechanical knitting device that generates a double layer of fabric using two sets of needles. This results in fabric that is more durable, thicker, and warmer compared to that produced by single jersey machines.

Double jersey knitting machines feature two sets of needles, allowing the production of fabrics twice as thick as single jersey fabrics. Rib and interlock are two common fabrics knitted by double jersey machines.

These machines have two needle beds operating in opposite directions and utilize cam systems to manipulate the needles for creating various stitch patterns. Yarns are fed through the machine's feeders, picked up by the needles, and manipulated by the cams to produce the fabric.

The double jersey knitting machine is utilized in producing a wide array of fabrics, including sweaters, cardigans, knitwear, blankets, and upholstery fabrics.

Advantages of Double Jersey Knitting Machine

(1) Capable of producing complex designs and intricate patterns.

(2) Produces a double layer of fabric, enhancing durability and suitability for diverse applications.

(3) Cost-effective and efficient in fabric production.

Double Jersey Circular Knitting Machine

6 results

Introducing our Double Jersey High Leg Circular Knitting Machine featuring a specially designed hydraulic roll cloth mechanism. Experience unparalleled precision with our accurate central lifting system, boasting an impressive accuracy of within 0.03 mm. Upgrade your knitting operations with this standardized, high-performance machine. Explore our range today!

Introducing our Double Jersey Velour Shearing Circular Knitting Machine Maker: available in sizes ranging from 26 to 34 inches and featuring a gauge selection of 14 to 28. With a wide range of feeders, from 42 to 54, this machine is perfect for creating plush fabrics like Pine Needle, Coral, Peacock, Pearl, Cashmere, and other luxurious materials. Explore our high-quality knitting machine for superior results in the textile industry.

Welcome to our High Speed Open Width Double Jersey Circular Knitting Machine Factory. We offer a range of machines with a diameter ranging from 26 to 44 inches, gauge options from 16 to 32, and 52 to 83 feeders. Our machines excel in seamless fabric processing, ensuring high efficiency and top-quality results. Explore our advanced knitting technology for all your fabric production needs.

High-Speed Double Jersey Circular Knitting Machine Provider: We offer a wide range of high-speed double jersey circular knitting machines with diameters ranging from 8 to 44 inches, gauges from 6 to 40, and feeders options of 16 to 88 or 106. Our machines are capable of producing interlock fabrics, elastic health cloth, twill, air layer, double mesh, and high-class men's or women's apparel, among other products. Choose our knitting machines for efficient and precise knitting operations.

Double Jersey Jacquard Knitting Machine Supplier: Our fully electronic Rib Transferred knitting machine is designed to meet your needs. With a diameter range of 26-38 inches and a gauge of 12-22, it offers versatility in producing high-quality knitted fabrics. Operating at a speed of 12-18 R.P.M with a powerful 5.5W motor, this machine ensures efficient and precise knitting. Trust our reliable supplier for your knitting machine requirements.

Manufacturer of Jacquard Circular Fabric Knitting Machine: Double Jersey, 26-42 Inch Diameter, 12-32 Gauge, 1.6 Feeders per Inch. Fully electronic and computerized for efficient operation. Explore our range now!

Total 6 Records, 12 records per page