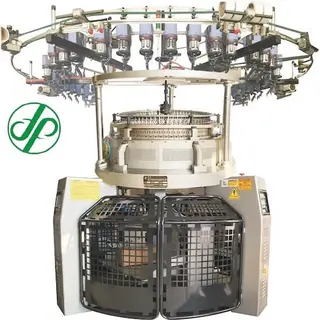

Open-width Circular Knitting Machines are a specialized type of textile machinery used for producing knitted fabrics. Unlike traditional circular knitting machines that produce tubular fabrics, open-width knitting machines are designed to create fabrics with open widths, allowing for larger fabric widths without seams. These machines come in two main types: single jersey open-width knitting machines and double jersey open-width knitting machines.

The single jersey open-width knitting machine is capable of manufacturing fabric without wrinkles, ensuring a smooth and seamless result. On the other hand, the double jersey open-width knitting machine utilizes advanced features such as a high-speed motor and a large-diameter cylinder to increase efficiency and productivity. It is equipped with an automatic cutting system to minimize fabric loss and a cloth collecting stick for processing fabrics of different sizes automatically.

Open-width circular knitting machines operate using a continuous loop of yarn, enabling the production of seamless fabrics. They are equipped with multiple needles and cam systems, allowing for versatile knitting patterns and designs. Additionally, these machines feature scale marks around their circumference to maintain distance between fabric ends, ensuring precise operation inch-by-inch.

The fabrication of open-width circular knitting machines is based on the single jersey tubular knitting machine design, which results in crease-free, smooth-textured fabrics. This design also allows for easy adjustment of fabric density, size, and thickness, thereby prolonging the life of the needles and equipment.

Advantages of Open-width Circular Knitting Machines

(1) Produce fabric of exceptional quality without any breaks or interruptions along its surface or center.

(2) Reduce fabric wastage during manufacturing processes.

(3) Enhance return on investment and bolster profitability through efficient operations.